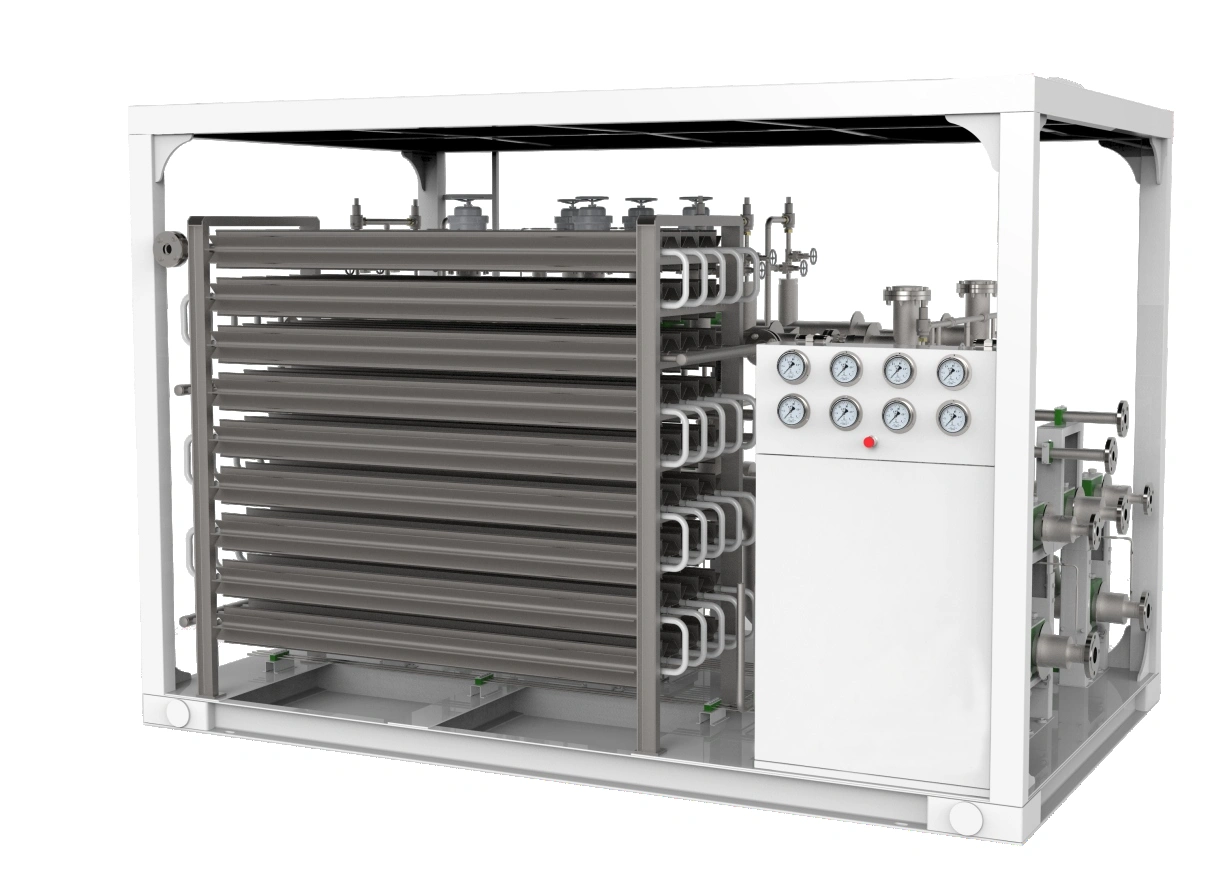

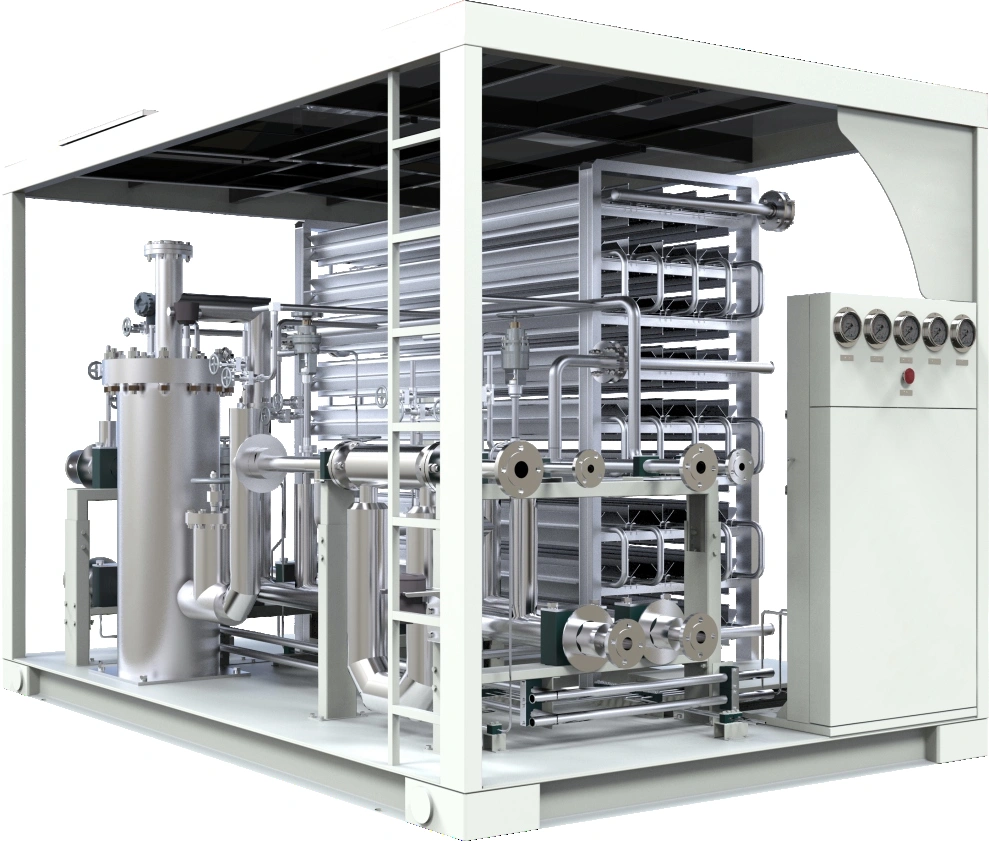

LNG cryogenic pump skid is the core equipment in the liquefied natural gas (LNG) transportation system. It is an integrated equipment consisting of cryogenic pump, skid-mounted base, pipeline system, control system and safety device. LNG gas filling pump skid has the functions of filling, unloading, saturation adjustment, etc. According to the configuration, it can be divided into two types: single pump skid and double pump skid.

* Modular design: prefabricated in the factory, easy to install on site

* Safe and reliable: multiple safety protection systems

* Energy-saving and efficient: optimized fluid channels

* Intelligent control: remote monitoring and operation

* Convenient maintenance: key components are easy to repair and replace

| No | Item | Data |

| 1 | Applicable medium | liquefied natural gas (LNG) |

| 2 | Dimensions | single pump: 4000*2250*2540 mm |

| 3 | Dimensions | double pump: 2200m*1000m*2000 mm |

| 4 | Design head | 220-280 m |

| 5 | Design speed | 5800 r/min |

| 6 | Design flow | 360 L/min |

| 7 | EAG heater | 150 Nm³/h |

| 8 | Booster | 200 Nm³/h |

| 9 | Air pressure test pressure before/after pump | 1.84/2.88 Mpa |

| 10 | Air tightness test pressure before/after pump | 1.6/2.5 Mpa |

| 11 | Design pressure before/after pump | 1.6/2.5 Mpa |

| 12 | Working pressure before/after pump | 1.0/1.6 Mpa |

| 13 | Design temperature | -196 ℃ |

| 14 | Working temperature | -162 ℃ |

| 15 | Pipe flange pressure | 4.0 Mpa |

| 16 | Motor power | 11 KW/15 KW |

| 17 | Power supply | three-phase 380 V 50 HZ |

| 18 | Weight | single pump: 3000 kg |

| 19 | double pump: 3500 kg | |

| 20 | Other | LNG cryogenic pump skid (single pump) supports 2 single-gun liquid filling machines |

| LNG cryogenic pump skid (dual pump) supports 4 single-gun liquid filling machines |

✅ LNG Storage & Terminals – Efficient transfer between tanks & tankers.

✅ LNG Truck Loading/Unloading – Fast, safe fueling for transport fleets.

✅ Marine Bunkering – Reliable LNG supply for ships & offshore vessels.

✅ Peak-Shaving Plants – Ensures stable LNG supply during high demand.

🔹 Proven Reliability – Tested in extreme conditions for long service life.

🔹 Customizable Solutions – Tailored flow rates, pressures, and control options.

🔹 Global Compliance – Certified for North America, Europe, and Asia markets.

🔹 Low Maintenance – Sealless design & corrosion-resistant materials reduce downtime.

Scan the QR code to follow us on WhatsApp

Scan the QR code to follow us on WhatsApp